The days of the “Dieselross F9,” German for “diesel horse,” the name of Fendt’s first tractor launched in 1930, are long gone. It was the precursor to a series of machines that over time established the brand as a leader in the field. While Fendt’s image is primarily associated with tractors today, it actually began its journey in agricultural mechanization as a manufacturer of equipment. Specifically, it started with a motorized sickle bar launched in 1928, catering to haymaking and cereal harvesting practices.

Therefore, it comes as no surprise that in recent times, nearly a century later, the German brand sought to reaffirm its origins by including mowers in its product range, equipment belonging to the “Slicer” family, featuring blades offered in trailed and mounted versions. The latter are further subdivided into front, rear, and combination types. Common across the entire range are cutting widths ranging from a minimum of two meters and 40 centimeters in lighter models suitable for smaller operations, including mountainous regions, up to triple-element work sites reaching nine meters and 60 centimeters in width, ideal for large plains farms and contract farming.

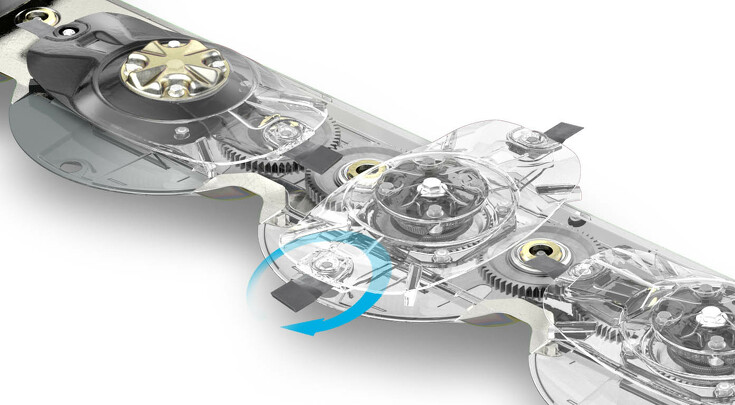

This comprehensive offering from Fendt originates from the “Streamline” sickle bars, structured around cylindrical gear transmissions and large discs, ensuring that the “Slicer” mowers maintain peak operational standards in all working conditions. Contributing to this are the mowers’ excellent maneuverability on uneven terrain, allowing them to consistently operate at the correct cutting height, between five and seven centimeters, regardless of the terrain’s contours. This feature maximizes both the quantity and quality of harvested forage while preserving the grass cover for quicker recovery between mowing cycles. Configured in this manner, the equipment ensures maximized crop cycles, making them less burdensome. This is further facilitated by the inclusion of cutting elements driven by cylindrical gears, operating at both 850 and 1,000 revolutions per minute. The first speed setting of the power take-off allows for the “Eco” mode, suitable for cutting regrowth with lower density, while the second is geared towards handling denser vegetation masses, such as the initial mowing of the year, particularly with grasses.

Regardless of the operating mode, consistent cutting quality is ensured by cutting discs driven by transmission pinions arranged in a row and characterized by large dimensions. This solution applies force directly to the first cutting disc, whose rectified and hardened gears then transmit it to the subsequent disc, utilizing a tooth overlap of three and a half points of contact. This design reduces the need for cutting modules per meter of working width, benefiting the smooth flow of harvested product and reducing energy consumption. Additionally, the absence of stopping points on the blade suspension allows it to rotate around the perimeter, extending its lifespan by enabling its use on both sides. When it’s time to replace the blades, this process is made easier by the “Comfort-Change” system, which facilitates swift removal and reinstallation using a specific tool provided as standard. Furthermore, the hexagonal transmission shaft and angular units feature a self-lubrication system that eliminates maintenance needs and downtime associated with machine stops.

Maximum Protection

No matter how advanced a mower may be, working in the field still poses some risks, such as those arising from overload or impact with foreign objects. To prevent such risks, Fendt technicians have equipped the “Slicer” mowers with specific solutions aimed at ensuring equipment longevity and full operational safety. Key to these goals is both the freewheel integrated into the gearbox, which prevents damage to the machine in emergencies, and the predetermined breaking point of the hexagonal shaft, allowing for quick resumption of work after replacing the damaged shaft. Similarly, the angular transmission is protected against overloads by the “DriveGuard” system, which disengages at four predetermined breaking points, thereby interrupting the transmission of motion.

Always Perfect Contours

Responsible for adapting the equipment to the terrain, safeguarding the grass cover, and minimizing the risks of forage contamination is the “TurboLift” system. This system allows for the adjustment of desired pressure before cutting begins, with the ability to modulate it during operation. This ensures that the “Slicer” mowers can react flexibly to different working conditions, autonomously recalibrating to ensure optimal operational efficiency. At the end of the activity, simply pressing a button causes the valve regulating the system to lock, completely releasing the pressure from the cutting unit, facilitating safe and easy equipment storage.